About the Department

The Department of Industrial and Manufacturing Engineering at Prince of Songkla University is well-equipped with human resources, machinery, equipment, and laboratories to provide services for personnel and students, as well as organizations offering academic services to society. These services include training in quality standards such as ISO 9002, ISO 14000, PM (Preventive Maintenance), TPM (Total Productive Maintenance), QC (Quality Control), 5S, and management principles. Additionally, the department conducts research in various industries, such as small-scale palm oil processing, metal cutting research, and research in metal casting and ceramics. Currently, the department offers undergraduate programs in Industrial Engineering and Production Engineering, master’s programs in Industrial and Systems Engineering, Logistics and Supply Chain Engineering, and Industrial Management, as well as a doctoral program in Industrial and Systems Engineering.

The Bachelor of Engineering in Industrial Engineering program focuses on the design, development, planning, control, operational research, management, and evaluation of integrated systems. It covers all aspects, including personnel, information, machinery, equipment, materials, energy, and finances, to meet established objectives. In essence, the program aims to optimize resource utilization and maximize efficiency.

The Bachelor of Engineering in Manufacturing Engineering program aims to produce engineers with a positive attitude, capable of integrating knowledge in science, technology, engineering, and mathematics to create innovations in manufacturing engineering. The program develops international-level skills and 21st-century competencies to address engineering challenges for the southern industry and the nation. Education is focused on Outcome-Based Education through diverse active learning methods, especially Problem-Based Learning, Project-Based Learning, Work-Integrated Learning, the CDIO (Conceive, Design, Implement, and Operate) Education Framework, and Service Learning. Moreover, the curriculum emphasizes aligning with the quality standards of the Accreditation Board for Engineering and Technology (ABET) in the United States to enable graduates to work effectively with engineers worldwide and solve complex problems in production engineering.

Vision and Mission of Manufacturing Engineering

| Vision

A leading engineering faculty in the nation, dedicated to developing engineers with global competencies and innovative capabilities to advance the southern region and the country. |

Mission

|

Vision and Mission of Faculty of Engineering

| Vision

Faculty of Engineering Leading the nation in producing engineers and create innovations with international potential to develop the southern region and the country sustainably (Faculty of Engineering ranked 1 of 5 in the country in 2026) |

Mission

|

Program Educational Objectives

The Program Educational Objectives for Manufacturing Engineering Program has been established and the following objectives are:

| PEO 1 | Graduates proficiently practice their profession in careers manufacturing engineering including product design, process design and planning, quality inspection and control. |

| PEO 2 | Graduates efficiently utilize state-of-the art technology from data analytics and Manufacturing. |

| PEO 3 | Graduates pursue advanced studies and use self-learning skills to advance their careers |

| PEO 4 | Graduates practice their professions with integrity, professionalism, and ethics, and contribute to the development of their communities and society. |

Program Constituencies

The consistencies of our Manufacturing Engineering program comprise of:

- Graduates of the program (Alumni)

- Employers of the graduates, and

- Industrial advisory board (IAB)

- Faculty

Graduates of the program (Alumni)

Graduates enhance the program's quality and reputation. Therefore, alumni provide important information about the attributes of graduates that employer’s need, which significantly impacts the determination of the program education objectives. The industrial and manufacturing engineering alumni are surveyed annually and are asked questions that relate to their current activities to find out how they currently meet the educational objectives of the program. The assessment helps to determine if any changes are required to help the future industrial and manufacturing engineering alumni perform better in their chosen profession. Alumni records are collected at the time of graduation and updated regularly so that as many alumni as possible are invited to participate in the online survey each year. A Google survey has been distributed to alumni and the results will be included in the SSR report.

Employers of the graduates

Employers of graduates from the program can directly reflect the desired attributes of the graduates, which the program must consider when determining the program education objectives. The program committee needs are assessed through an annual survey of managers who work directly with the graduates. The program committee also assists in the evaluation of the survey results from the industry stakeholders, alumni, and graduating students.

Industrial advisory board (IAB)

The IAB represents several industry-related regional companies and organizations which consistently recruit manufacturing engineering graduates. The IAB provides feedback and reviews the program education objectives to ensure they align with the true needs of the employers of the graduates. As employers of the students, the IAB constituency’s needs are assessed through an annual survey of managers who work directly with the graduates. The IAB also assists in the evaluation of the survey results from the industry stakeholders, alumni, and graduating students. The Faculty of Engineering has appointed the IAB Committee for the Manufacturing Engineering program, with the list of committee members shown in Table 2-2. The IAB committee met on July 4, 2024, to review the PEOs proposed by the Manufacturing Engineering Program. After discussion, the IAB agreed with the PEOs without any revisions.

Members of Industrial Advisory Board (IAB)

Faculty

The expertise of our dedicated faculty members is crucial in shaping our program’s educational objectives. They bring a wealth of knowledge and academic experience, contributing to the alignment of our objectives with academic rigor and industry relevance. One of the most important roles of the program faculty is to collect feedback about whether our PEOs satisfy their needs and to update/revise the PEOs based on those feedbacks as the faculty deems appropriate.

Students Outcome (SOs)

Graduates of the Manufacturing Engineering Program will have attained the following outcomes by the time of graduation.

- An ability to identify, formulate, and solve complex engineering problems by applying principles of engineering, science, and mathematics

- An ability to apply engineering design to produce solutions that meet specified needs with consideration of public health, safety, and welfare, as well as global, cultural, social, environmental, and economic factors

- An ability to communicate effectively with a range of audiences

- An ability to recognize ethical and professional responsibilities in engineering situations and make informed judgments, which must consider the impact of engineering solutions in global, economic, environmental, and societal contexts

- An ability to function effectively on a team whose members together provide leadership, create a collaborative and inclusive environment, establish goals, plan tasks, and meet objectives

- An ability to develop and conduct appropriate experimentation, analyze and interpret data, and use engineering judgment to draw conclusions

- An ability to acquire and apply new knowledge as needed, using appropriate learning strategies

Note: Minimum requirement to achieve the SO is 70%, which is calculated based on 80% weight of direct assessment (40% weight of each course) and 20% of indirect assessment.

Student Admission

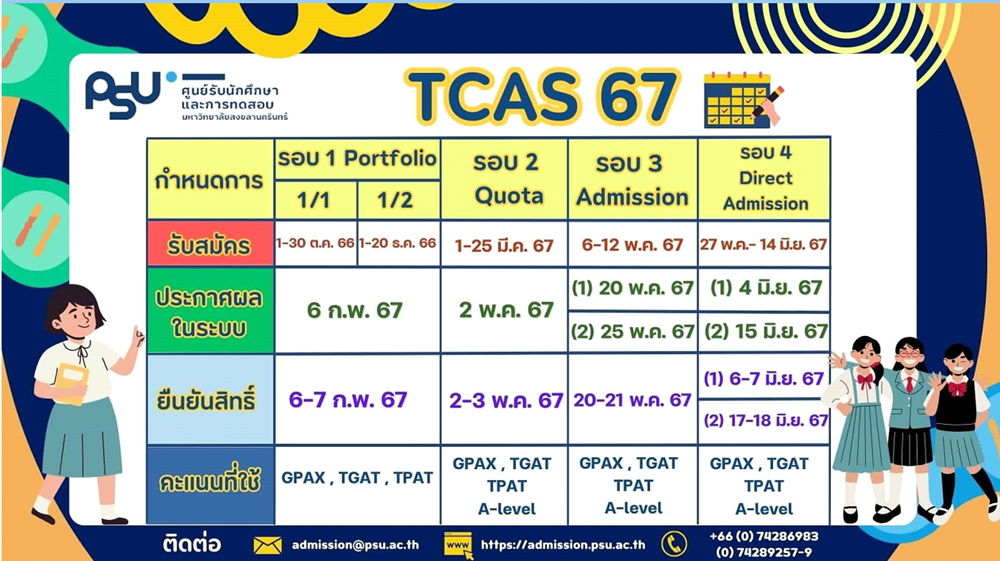

In order to qualify for admission to the Manufacturing Engineering Program, applicants must possess a high school diploma or an equivalent certificate in the field, or be enrolled in Mathayom Suksa 6 (grade 12). The cumulative Grade Point Average (GPA) obtained throughout a three-year study period in high school serves as a general qualification requirement and condition for enrollment. In addition to the GPA requirement, applicants must hold a score of 7 specific subjects (Thai, Mathematics I, Social Studies, Physics, English, Chemistry, and Biology. The scores of Thai General Attitude Test (TGAT) and Thai Professional Attitude and Academic Test for Engineering Professional (TPAT3). The criteria for admitting the Manufacturing Engineering Program in each TCAS round are different as presented in Table 1-1. These requirements are according to Engineering Faculty criterion.

Manufacturing Engineering Program Admission Requirement for TCAS system

| Subject | TCAS 1 | TCAS 2 | TCAS 3 | TCAS 4 |

| GPAX | ✓ | ✓ | ✓ | ✓ |

| Portfolio | ✓ | ✓ | ||

| Interview | ✓ | ✓ | ||

| Mathematics I | ✓ | |||

| Physics | ✓ | |||

| Biology | ✓ | |||

| English | ✓ | |||

| Chemistry | ✓ | |||

| Thai | ✓ | |||

| Social Studies | ✓ | ✓ | ||

| TGAT | ✓ | ✓ | ✓ | |

| TPAT3 | ✓ | ✓ |

The 7 specific subjects as well as TGAT/TPAT3 are tested by the National Institute of Educational Testing Service or NIETS in order for universities to consider the applicants based on their score through the Clearing-House system. The scores of individuals applicants for TCAS admission are subsequently ranked based on their performance in the interview process, which takes place from December to June. The interview procedure is coordinated by the Faculty of Engineering in conjunction with the Department and the program. The selected applicants in each round will be announced according to TCAS schedule from February to June each year. The applicants have two opportunities to select Manufacturing engineering program: directly upon the admission and after completing their first semester at university (particularly for the applicants selecting general engineering major). The admission score and the total number of freshmen enrolled in TCAS round 3 for the academic years 2022-2024 are presented in Table 1-2 .The Faculty of Engineering regards and employs the national ranking from the TCAS admission process as a crucial piece of information to evaluate the educational strategic planning for attracting new students and maintaining competitiveness in order to ensure the quality and quantity of freshmen enrollment each year. Additionally, Table 1-3 presents the number of students for each academic year, categorized by their year of study and year of graduation.

Total freshman enrollment and admission statistics in TCAS 3 for the Manufacturing Engineering Program, Academic year 2022-2024.

| Academic Year | Admission plan | National Admission Score for Manufacturing Engineering at PSU | Freshman enrollment (Direct Admission) | |

|---|---|---|---|---|

| Max | Min | |||

| 2022 | 40 | 35.02 | 36.91 | 5 |

| 2023 | 40 | 50.94 | 54.71 | 20 |

| 2024 | 40 | 47.21 | 52.61 | 20 |

Number of students for each academic year (2020-2024), categorized by their year of study and year of graduation.

| Academic Year | Plan | Number of Students | Number of Graduation | ||||

|---|---|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 4th | 5th | >5th | ||

| 2020 | 40 | 53 | 53 | 51 | 26 | 23 | 2 |

| 2021 | 40 | 52 | 52 | 49 | 25 | 20 | 4 |

| 2022 | 40 | 41 | 41 | 35 | 17 | 13 | 5 |

| 2024 | 40 | 44 | 44 | 43 | 35 | 6 | 2 |

Admission to the Chemical Engineering Program for Academic year 2022.

Graduation Requirements

In order to graduate from the Manufacturing Engineering Program, Prince of Songkla University, a graduating student has to fulfill all of the following requirements listed below in order to be awarded the degree of Bachelor of Engineering in Manufacturing Engineering:

- Complete and pass all the courses as required by our program (136 credits detailed as follows)

- Achieve minimum Engineering cumulative GPA of 2.00.

- Pass the English language proficiency assessment criteria announced by Prince of Songkla University.

- Pass the senior (capstone) project course;

- Pass the Engineering training course

- Student must complete extra-curricular activities per university requirement

Before graduation students are required to submit a request form for expected graduation to the Academic Affairs Unit within the second semester of the fourth year. The graduation request form must include the list of registered courses for all semesters as downloaded from SIS online system (https://sis.psu.ac.th/). The staff of the Academic Affairs Unit is responsible to check the correctness for all registered courses to ensure that all graduation requirements are met and then endorsed by the Associated Dean for Academic Affairs before submission for Dean’s approval. The graduation’s request is approved and certified by Prince of Songkla University Council for the last step and the academic work is then recorded officially as shown in the transcript. Students who have sufficient hours for participating in extra-curricular activities of both enhancing performance activity and interested activity as specified by the University will appear in the transcript. The activity approval can be used in the student’s application for employment to certify the student’s achievements in various skills enhancement activities.

| Course Structures | Credits |

|---|---|

| General education | 24 credits |

| 001-102 The King’s Philosophy and Sustainable Development | 2 credits |

| 001-103 Idea to Entrepreneurship | 1 credits |

| 200-103 Modern Life for Green Love | 2 credits |

| 200-111 Into Engineering World | 2 credits |

| 226-001 Benefit of Mankind | 1 credits |

| 388-100 Health for All | 1 credits |

| 890-0xx GenEd 6: Language and Communication | 2 credits |

| 895-001 Good Citizens | 2 credits |

| 950-102 Happy and Peaceful Life | 3 credits |

| General Education Electives | |

| GenEd 6: Language and Communication | 1 credits |

| General Education Electives | |

| GenEd 7: Aesthetics and Sports | 3 credits |

| General Education Electives | |

| GenEd 5: Systematic Thinking | 2 credits |

| General Education Electives | |

| GenEd 5: Logical and Numerical Thinking | 2 credits |

| Math & Basic Sciences | 30 credits |

| 200-112 Fundamental Mathematics for Engineer | 3 credits |

| 200-113 Fundamental Physics for Engineer | 3 credits |

| 200-114 Fundamental Chemistry for Engineer | 2 credits |

| 226-102 Mathematics I | 3 credits |

| 226-104 Fundamental Chemistry Laboratory | 1 credits |

| 226-201 Statistics and Probability | 3 credits |

| 226-202 Mathematics II | 3 credits |

| 226-316 Chemistry I | 3 credits |

| 226-367 Numerical Methods | 2 credits |

| 332-101 Fundamental Physics | 3 credits |

| 333-101 Fundamental Physics Laboratory | 1 credits |

| 342-102 General Chemistry II | 3 credits |

| Engineering Topics | 70 credits |

| 200-115 Basic Electrical Engineering | 3 credits |

| 200-116 Basic Engineering Programming | 3 credits |

| 200-117 Basic Engineering Drawing | 2 credits |

| 221-101 Fundamentals of Machinery | 3 credits |

| 226-101 Introduction to Manufacturing Engineering | 1 credits |

| 226-103 Thermodynamic and Heat Transfer | 3 credits |

| 226-203 Fundamentals of Machinery | 3 credits |

| 226-211 Manufacturing Processes Module | 5 credits |

| 226-221 Law, Work System, and Safety in Manufacturing | 2 credits |

| 226-204 Computer Aided Product Design and Drawing Module | 5 credits |

| 226-212 Forming Technology | 3 credits |

| 226-213 Tool Engineering | 3 credits |

| 226-231 Quality Control and Management for Manufacturing | 3 credits |

| 226-241 Engineering Economy and Decision Making | 2 credits |

| 237-111 Engineering Materials | 2 credits |

| 200-107 Internet of Things for Digital Life | 2 credits |

| 226-311 Machining Engineering and Machinery Technology Module | 5 credits |

| 226-321 Manufacturing Automation and Material Handling for Digital Factory Module | 5 credits |

| 226-351 Integrated Productivity Management Module | 5 credits |

| 226-312 Machine Design and Engineering Analysis | 3 credits |

| 226-361 Skills for Professional Manufacturing Engineer | 1 credits |

| 1st Option-Project Education | 12 credits |

| 226-461 : Manufacturing Engineering Project I | 3 credits |

| 226-462 : Manufacturing Engineering Project II | 6 credits |

| 226-465 : Case Study and Industrial Plant Visit | 3 credits |

| 2nd Option-Cooperative Education | 12 credits |

| 226-463 Cooperative Education I | 6 credits |

| 226-464 Cooperative Education II | 6 credits |

| Electives courses | 6 credits |

| 2 Manufacturing Engineering Electives courses | 6 credits |

| Total | 136 credits |

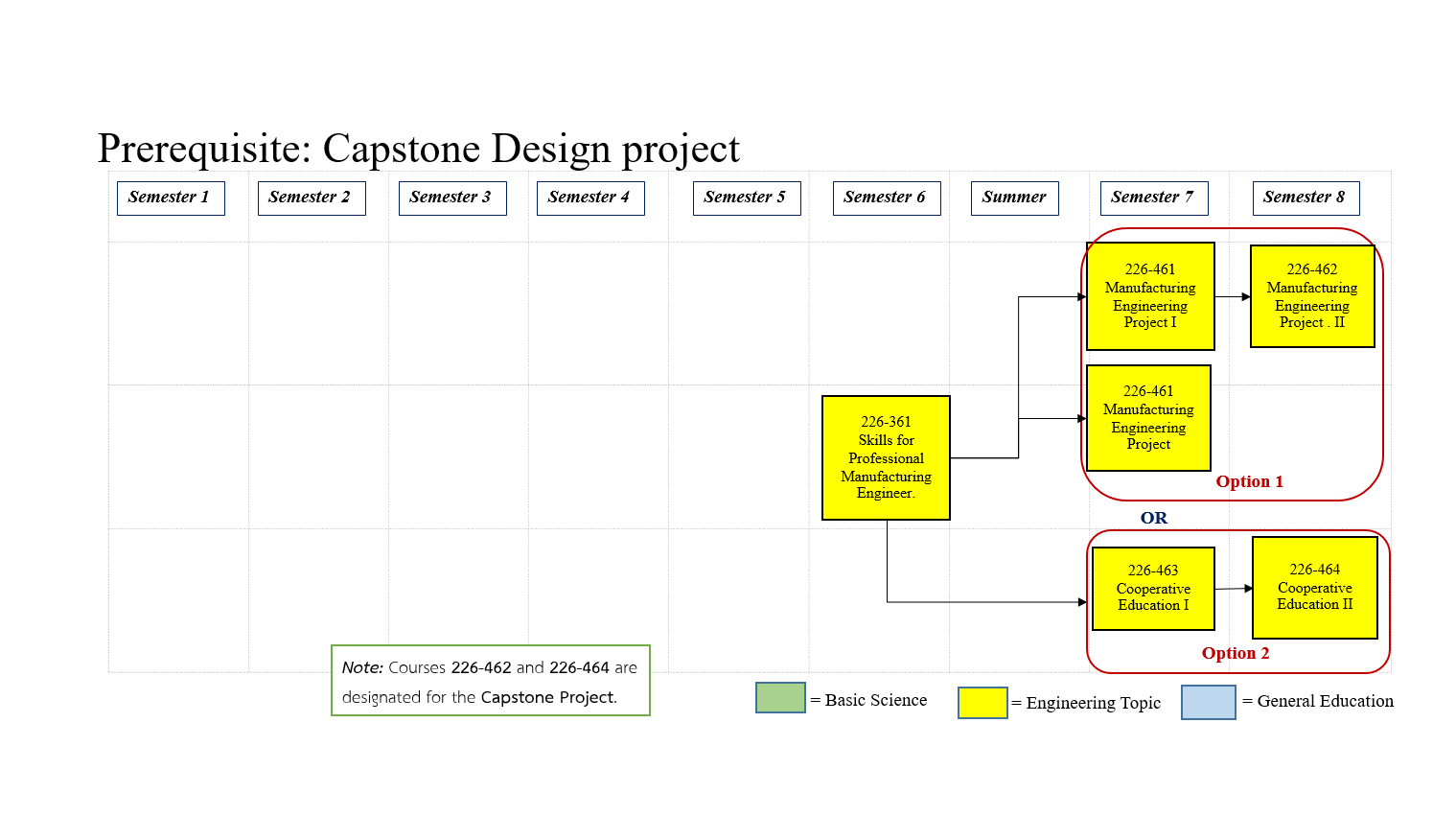

Capstone Design project

In the final year of the Manufacturing Engineering Program, students must complete the Senior Capstone Design project, specifically "226-462 Manufacturing Engineering Project II." These capstone projects focus on real-world manufacturing engineering challenges, incorporating economic and design constraints in line with relevant codes and standards. Students, working in multidisciplinary teams, develop design solutions for open-ended, real-world engineering problems under multiple realistic constraints. When possible, these courses are co-taught by a practicing professional engineer to enhance the project's realism. Students must consider the project’s cost, environmental impact, and related social and political issues, while ensuring technical accuracy in accordance with local zoning ordinances and subdivision regulations. Each team is required to submit a written technical report and publicly present their design solution. Typically, the selected projects for "226-462 Manufacturing Engineering Project II" involve site development or other general manufacturing engineering issues, with the design codes and standards specified to align with real-world implementation.

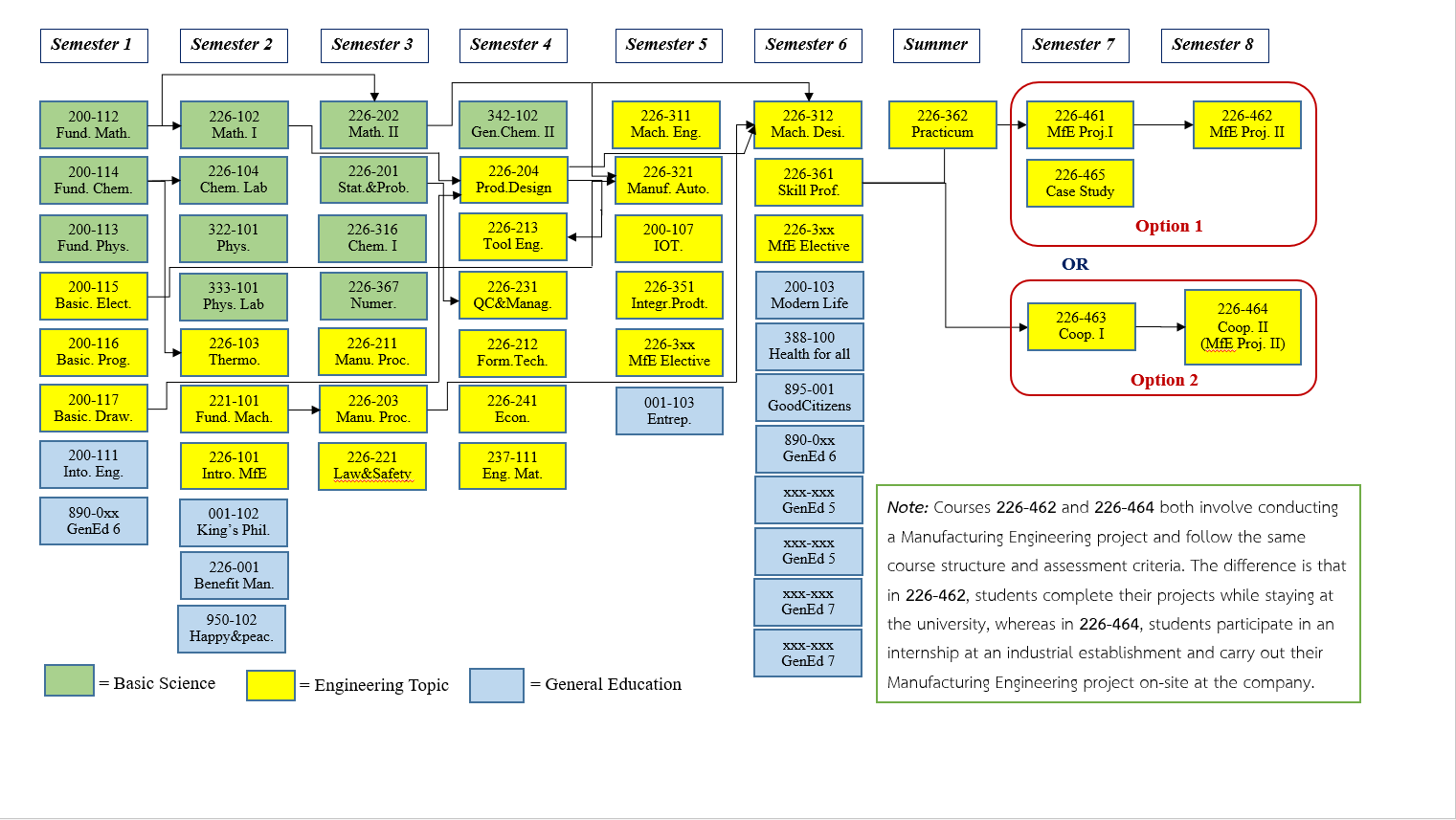

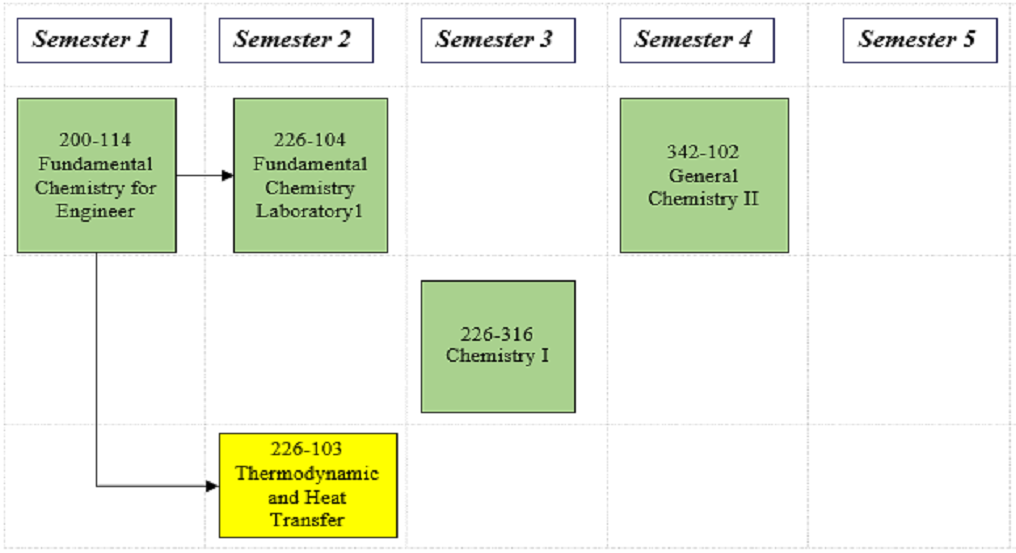

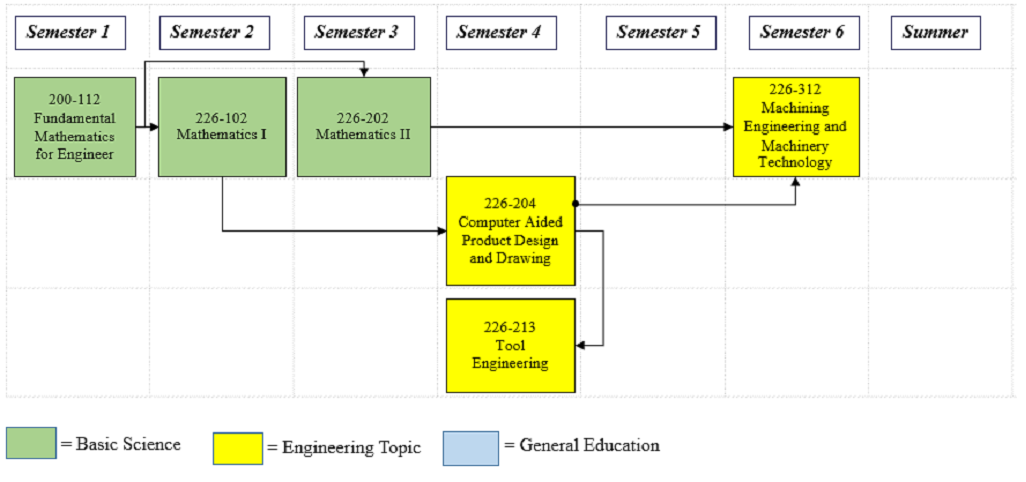

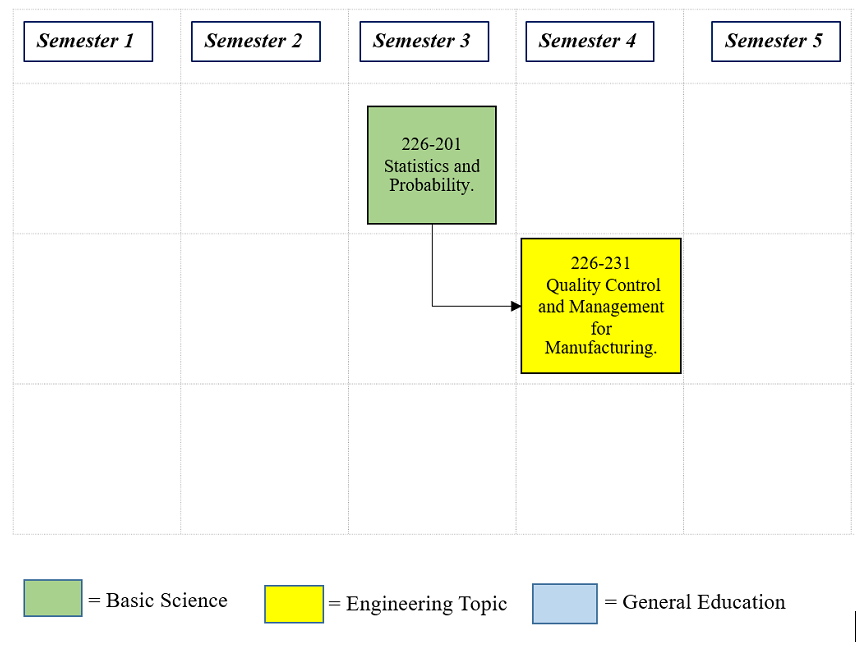

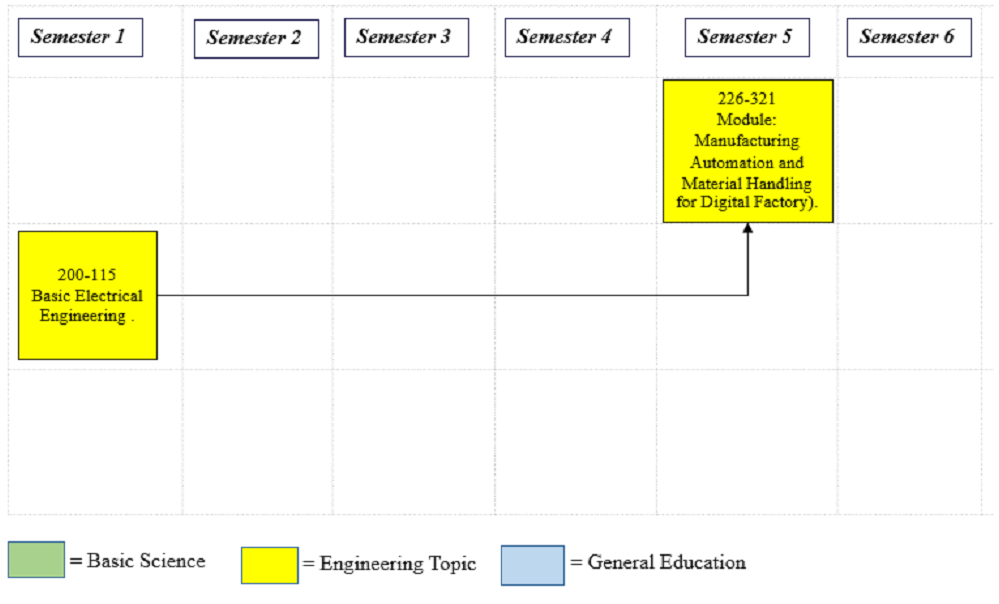

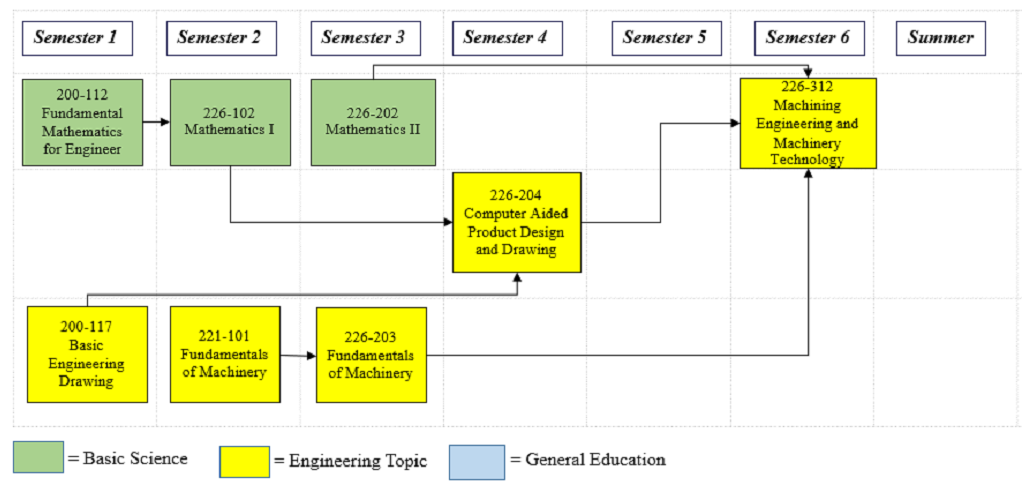

The figures below show a flow chart for the curriculum and indicates all pre-requisite and co-requisite courses including the prerequisites for chemistry, physics, mathematics, chemical engineering, and Manufacturing engineering Project.

A flow chart for the Manufacturing Engineering curriculum

Prerequisite: Chemistry

Prerequisite: Mathematics

Prerequisite: Statistics

Prerequisite: Automation

Prerequisite: Applied Engineering

Prerequisite: Capstone Design project

Program Accreditation

The Bachelor of Engineering in Manufacturing Engineering at Prince of Songkla University has been in Recognition of Engineering Degree Qualification by The Council of Engineers Thailand (COET) since 1997 for practicing the Regulated Engineering Profession.